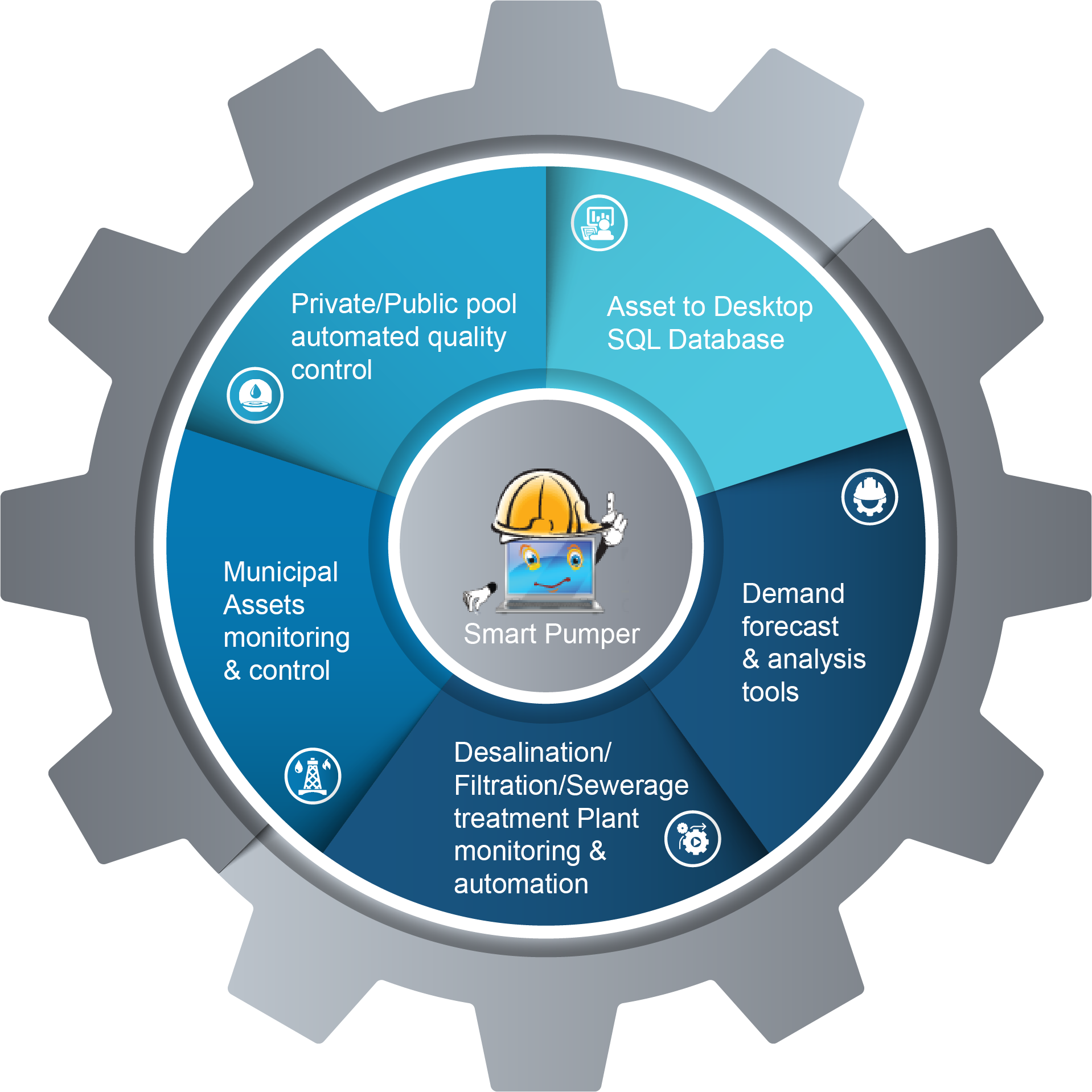

Water Resource Management

Smart Pumper TM is a proven hybrid technology (PLC+SCADA)

With 6 forms of communication built-into one box to control and monitor most anything (4G, Ethernet, Modbus, RS232, 900 MHz and 802.11). The Smart Pumper Integration Team delivers all pieces and parts needed to provide turnkey solutions; including material procurement, assembly, installation, activation, training and back room diagnostic support. Want Data and Control of remote sites on your desktop or other devices? The Smart Pumper “one box – IoT” does it all, providing a simple cost effect turnkey solution that ends the ad hoc approach experienced by many.

With 6 forms of communication built-into one box to control and monitor most anything (4G, Ethernet, Modbus, RS232, 900 MHz and 802.11). The Smart Pumper Integration Team delivers all pieces and parts needed to provide turnkey solutions; including material procurement, assembly, installation, activation, training and back room diagnostic support. Want Data and Control of remote sites on your desktop or other devices? The Smart Pumper “one box – IoT” does it all, providing a simple cost effect turnkey solution that ends the ad hoc approach experienced by many.

- Smart Pumper Data logs every Operational Parameter.

- Provides Remote Diagnostic Capability.

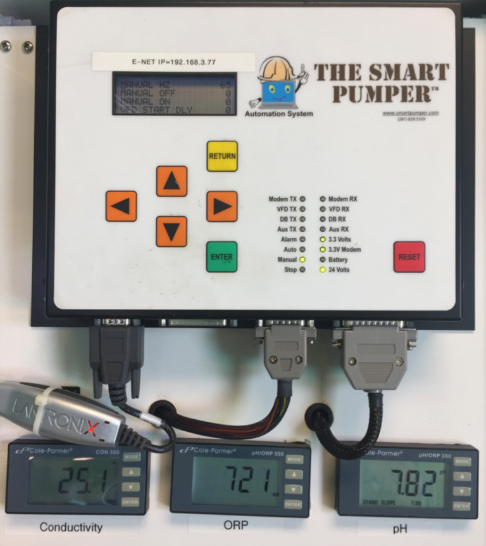

- Water Quality Alerts (i.e., pH, ORP, Conductivity, and more).

- Data helps Predict Failures and Defines Pump Problems.

- 52+ Reports (Graphic, Excel and Table Formats), Including VFD electrical data.

- Control & Monitor Pumps, Electrical generators/motors Water filtration/desalination facilities, Any VFD – Any Horse Power – Any Meter!

- Sensor Types (All) Provided and Supported Flexible, Scalable and Actionable

- 8 A-D (Nameable, Scalable and Actionable)

- 8 Digital Outputs

- 5 Digital Inputs

- Plus, Modbus

KEY BENEFITS:

- Automated chemical injection and VFD control.

- Control Relays & Switches for Motor Control beyond VFDs.

- Connect real time pool/tank data and conditions to your maintenance center.

- Alerts authorized teams to real time warnings and potential issues.

- Control and monitor pool and chemical dosing pumps.

- Control Proportional Valves

- Data logs 52 variables and processes in real time to automates pool functions.

- Prioritize work scheduling and work flow on view assets page.

- Protects people, pumps, pipelines, tanks, and more.

- Optimizes operations and reduces HSE risk for less capital cost.

SALT WATER DISPOSAL FACILITIES

KEY BENEFITS:

- Connects Saltwater disposal and production sites to authorized managers.

- Protects people, injection lines, monitors tank levels and more.

- Optimizes your time providing remote control of your facilities from anywhere.

- Data logs 52 variables and processes data in real time.

- Matches pump output to fluid in-flow for the smoothest and safest operation reducing on/off cycles, wear and energy demand.

- View asset page messaging helps prioritize work scheduling and work flow.

- Monitor multiple tanks levels, quantifies volumes, collects meter data, provides automatic chemical injection, ordering, inventory and delivery verification and more.

- Reduces HSE risk and capital cost.

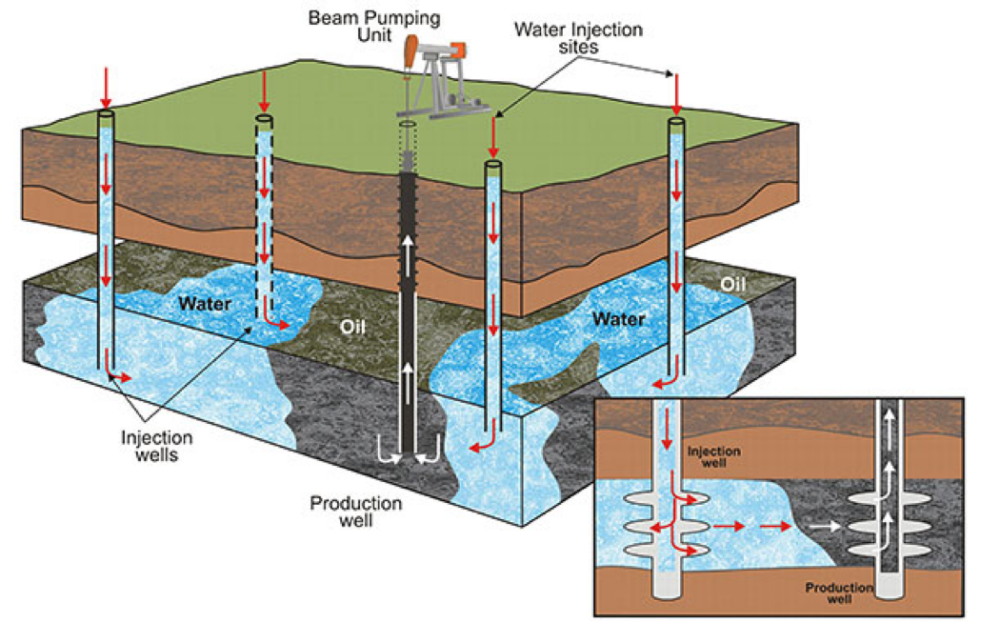

AUTOMATED WATER FLOODS

Automated Offtake(s) Based on Real Time Fluid Level to Designated Fluid Height Above Pump Selected. Receive Alerts as Pump Speed Automatically Increases to Compensate for the Effect Caused by Injection Well(s). Know What Well Responds First and Capture the Incremental Increase Potential as It Occurs.

Regulate Proportional Valves at your Manifold based on Injection Pressures to Distribute Water to Injection Wells More Evenly.

Monitor and Control:

- Injection Pump Automation Will Match Water Supply In-Flow

- Chemical Injection Pump Automation Will Match Injection Pump Speed

- Injection and Flow-Line Pressure Data together with High/Low Pressure Warnings and Faults Reduce HSE Risk and Provides Valuable Reservoir and Pipeline Information

- Real Time Wellbore Fluid Level, Down-Hole Pressure and Temperature Data Provides Reservoir Engineers Valuable Modeling Information

- Tank Levels, High and Low Warning and Faults, Inventory and Sales Records

- Collects Meter Data; Electro Magnetic, Velocity, and Turbine (A-D, Pulse and Modbus)

Turnkey System Solutions, Procurement, Integration, Installation, Training and Back Room Diagnostic Support Provided

- Set HSE Warnings and Fault Conditions for All Aspects of the Operation

- Control and Monitor VFDs used with Primary and Secondary Injection Pumps

- Provides VFD Data for Remote Diagnostics of Primary Electrical Conditions such as High and Low Voltage, kW, Hp, Power Outage, Phase Out, Motor Ground Faults, etc. And more…

PRODUCED & FRAC WATER MANAGEMENT

- Meter from all Sources and Measure Supply to End User.

- Any Meter Type (Electro Magnetic, Vortex Velocity and Turbine).

- A-D, Pulse (Clean and Dirty Signal) plus Modbus.

- Account for Royalty and Non-Royalty Production.

- Calculated Inventory Total and by Site and Territory (Reservoirs and Tanks).

- Predicts Fill Rate and Days to Empty.

- Any VFD – Any Horse Power – Any Meter

- VFD types Provided ABB through Westinghouse

- Data Log 52 Inputs Including VFD electrical data

- Sensor Types (All) Provided and Supported

- Flexible, Scalable and Actionable

- 8 A-D (Nameable, Scalable and Actionable)

- 8 Digital Outputs

- 5 Digital Inputs

- Plus, Modbus,

- Sensor, VFD and Meter Data (52+ Variables) Logged into SQL Data Base

- HMI Provide and can be Mapped into preferred HMI

- Control & Monitor Chemical Pumps & Associated Tanks

- Control Relays & Switches for Motor Control beyond VFDs

- Control Proportional Valves

- Control & Monitor Electric Generators

- Control & Monitor Diesel Motors